Introduction

We want to share our enthusiasm for our flagship product, gum ghatti, with you. No natural or chemically synthesized product can offer this natural gum's unique properties and multi-faceted functionality. Our team aims to provide our customers with the highest-quality material while ensuring sustainable and ethical sourcing and delivering tailored customer service.

Gum Ghatti is a complex polysaccharide with versatile properties. It is used in various industries, from the food industry, which acts as a stabilizer and emulsifier, to the pharmaceutical sector, where it is employed as a binder or a film-forming agent.

It is also widely used as a superior alternative to gum arabic in the food flavor and color industry due to its 4x better emulsification and stabilization capacity.

Origins and Harvesting

Gum Ghatti is the amorphous translucent exudate of the Anogeissus Latifolia tree, a member of the Combretaceae family. The tree occurs throughout much of India, more commonly in dry deciduous forests.

The gum is locally called Dhawda. The color varies from whitish-yellow to amber depending on factors like the proximity of the tear to the bark, the length of time it has remained on the tree before being picked, and the age of the product in storage.

The exudates are hand-picked by the locals and laid to dry in the sun for several days before being delivered directly or via authorized forest contractors to our processing plants.

Chemical Properties and Solubility

Gum Ghatti is a complex polysaccharide of high molecular weight. It occurs naturally as a mix of calcium, magnesium, potassium, and sodium salt. Complete hydrolysis has shown that it is composed of L-arabinose, D-galactose, D-mannose, D-xylose, and D-glucoronic acid in a molar ratio of 10:6:2:1:2 plus traces less than 1% of 6-deoxyhexose.

Gum Ghatti is a water-soluble gum that can be dispersed in hot or cold water to form a colloidal solution. It dissolves in water by 80 to 90%. Small amounts of acid or alkali do not affect ghatti dispersions, as the gum acts as a buffer and reverts to its normal pH of about 4.8. Additionally, Ghatti shows good emulsifying properties.

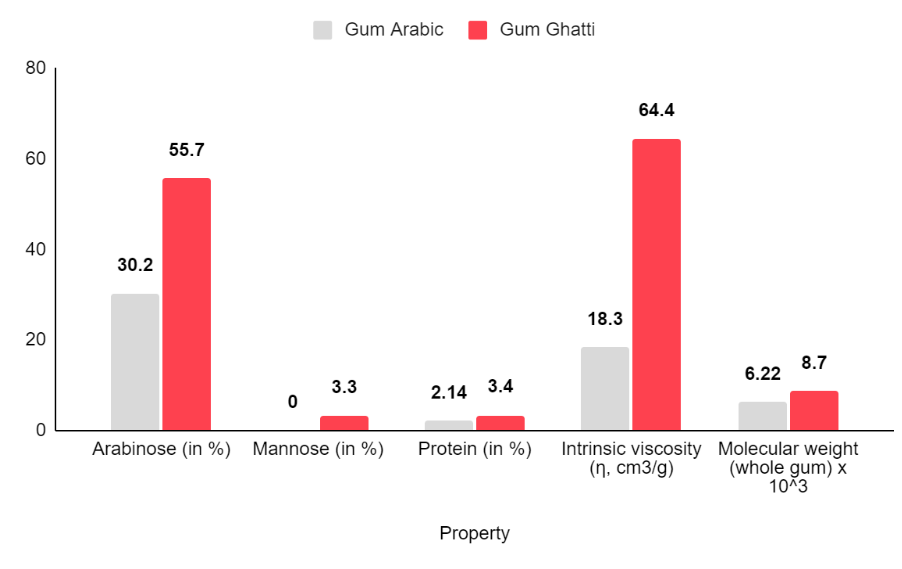

4x better performance compared to Gum Arabic

Gum Ghatti is often considered and used as a superior alternative to Gum Arabic/Acacia due to its 4X better emulsification and stabilization capacity. Moreover, these gums are also used synergistically together to reduce costs while maintaining the same viscosity.